In the precision world of mobile phones, the seemingly simple action of plugging and unplugging the Type-C interface is actually a "mechanical contest" that affects user experience and product lifespan.If the plugging and unplugging force is too large, users will complain about the effort and the interface will be easily damaged;if the plugging and unplugging force is too small,the connection will be unstable,risking interruptions in charging and data transmission. How to accurately measure the force "between millimeters" to ensure that the Type-C interface of each mobile phone is just right? Ligent Sensor’s S-type tension and compression sensor is playing the role of the core "sensory nerve" in this precision test.

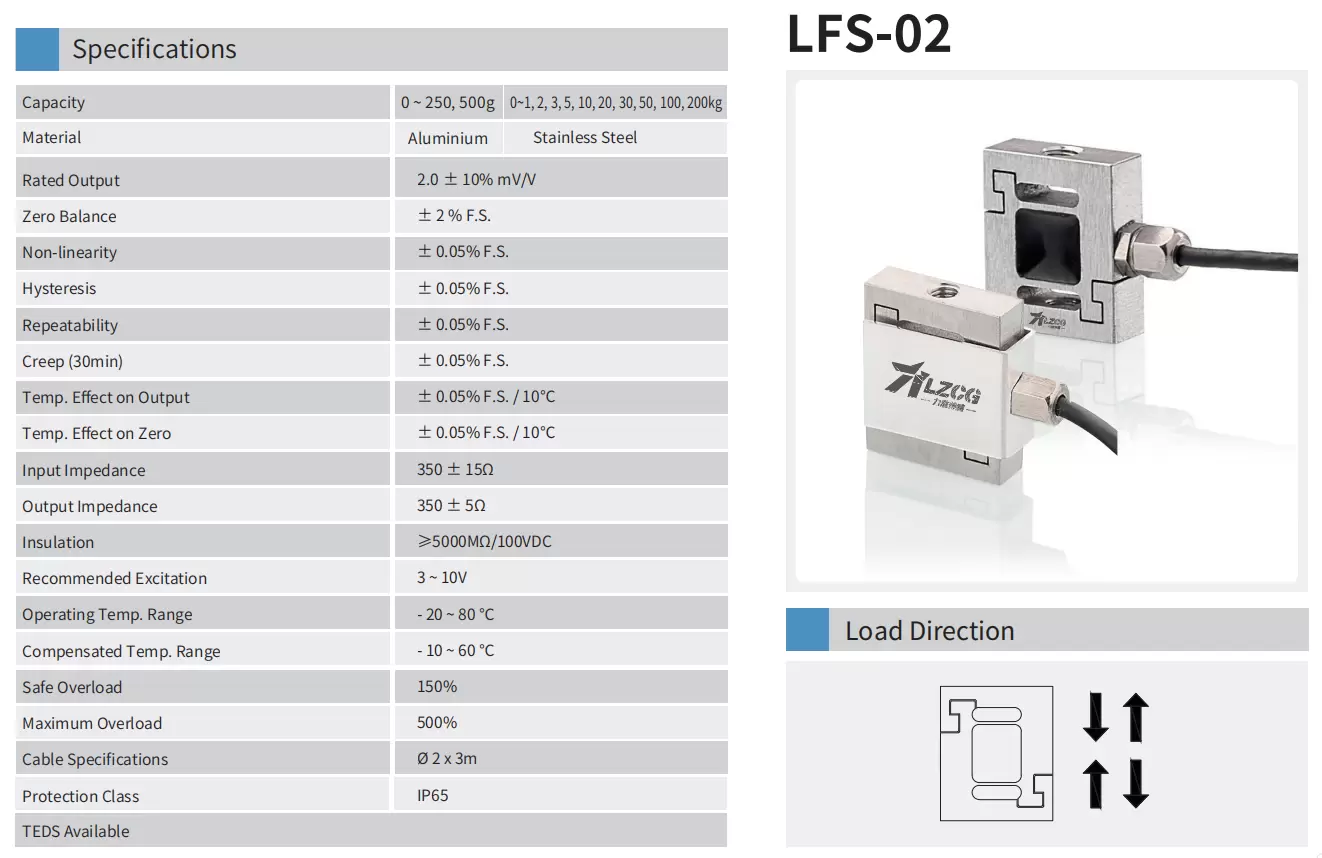

In the field of precision testing of Type-C interfaces on mobile phones, the LFS-02 S-type tension and compression sensor from Ligent Sensor has successfully broken through the technical barriers of micro-forces and dynamic changes measurement with its four core advantages.

1. Milligram-level resolution, every detail is visible:

The insertion and extraction forces typically range from tens to hundreds of grams (much less than kilogram-level force),yet require extremely high precision (even to distinguish changes of several milligrams) to evaluate the experience difference and structural stability.In response to this challenge, the LFS-02 series has specially launched a customized range solution of 0-250g/500g/1kg.By adopting high-sensitivity strain gauges and integrating exclusive micro-stress structural design, it achieves non-linear error control within ±0.05% FS, enabling clear resolution of force value changes as low as 0.1mg. This means the sensor can accurately capture the subtle force differences between "silky" and "stuck" insertion/extraction experience, providing more accurate data support for interface structure optimization.

2. Ultra-fast dynamic response, restore the real plug-in and unplug process

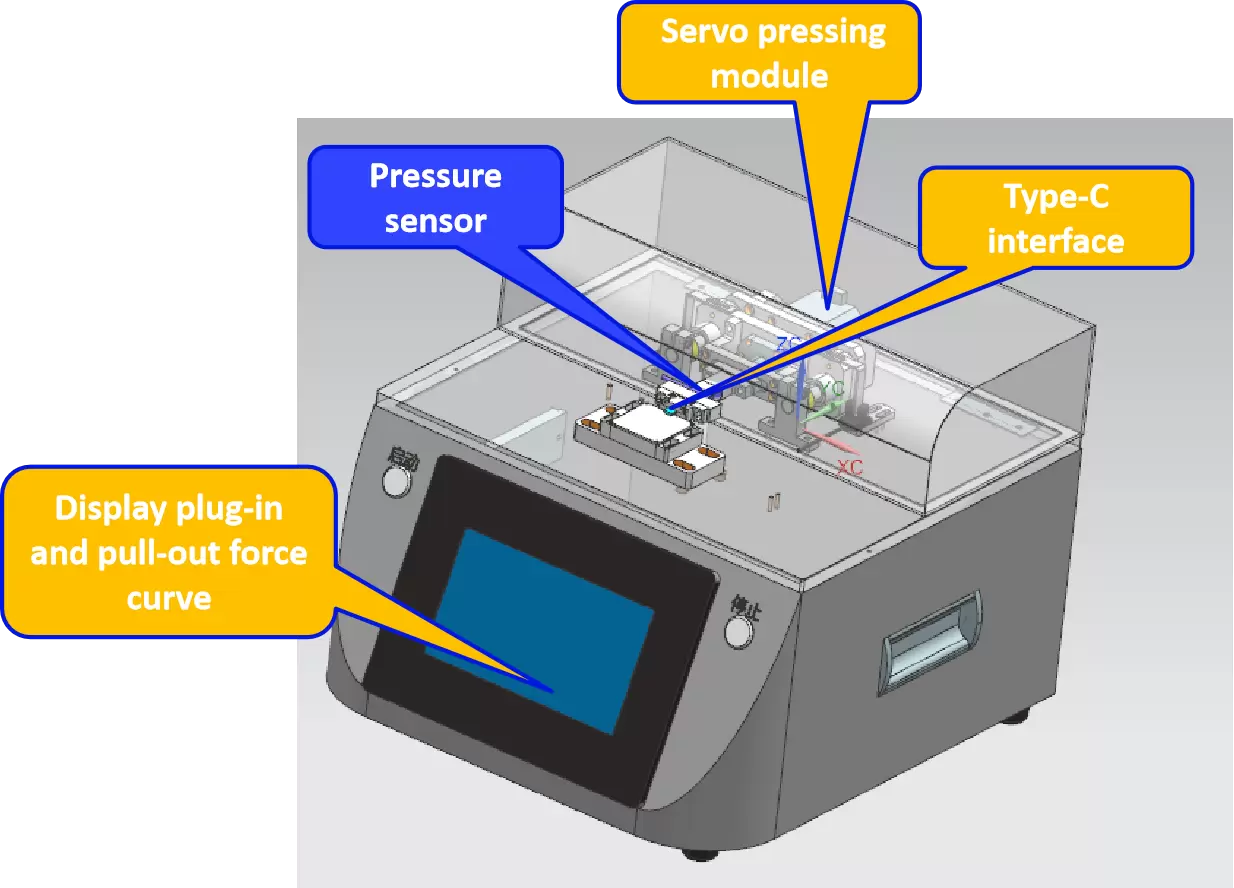

The plug-in and unplug process is fast and non-static.The sensor needs to respond quickly and accurately record the dynamic force change curve throughout the process (insertion force peak, holding force, extraction force peak, friction change, etc.), rather than just a static maximum value.With fast response speed, the sensor can track and record the millisecond-level dynamic fluctuations of force in real time during the entire plugging and unplugging action, generating a complete force-displacement (time) curve.This helps engineers accurately define the optimal plug-in force range, so that every plug-in and unplug is smooth and comfortable, and improve user satisfaction.

3. S-type structural design, compact and resistant to eccentric loading

The tooling space in the plug-in force test is usually limited, and the sensor needs to be compact and flexible.Meanwhile, minor lateral forces or eccentric loading may occur during the testing process.

The compact S-type structural design (with a minimum size of 16mm×19.1mm×6.7mm) makes it easy to integrate into the automated test fixture with limited space. Its unique structure endows excellent resistance to lateral forces and eccentric loading.Even in the non-ideal centering insertion and extraction process (simulating possible improper operation by the user), it can output accurate core plug-in force data to ensure the validity of the test results.

4. Industrial-grade durability, zero attenuation after millions of tests

Test equipment requires high-frequency and long-term operation. The sensor must ensure that the data is stable and reliable after thousands of tests.

The LFS-02 sensor body is made of high-strength aluminum alloy or stainless steel with good protection performance.After strict calibration and aging treatment, it ensures that on the 24/7 uninterrupted automated plug-in test line in the mobile phone factory, after tens of thousands of cycles, it still maintains long-term stability and measurement accuracy, providing a solid data foundation for quality control.

5. Intelligent adaptation, seamless connection with Industry 4.0

The instrumentation of the sensor can provide rich interfaces and seamless integration: It provides standard analog quantity (such as 0-10V, 4-20mA) or digital output (such as RS232/RS485), which can be easily connected to various PLCs, data acquisition cards or special test instruments to build an automated test system.The sensor outputs real-time force value signals throughout the insertion and extraction process. The data acquisition system records the complete force-time curve, calculates key indicators (such as maximum insertion force, maximum extraction force, plugging and unplugging force attenuation rate, plugging and unplugging times, etc.), and compares them with the preset qualified standards to automatically determine product passes or fails.

Ligent Sensing: Expert Partner for Micro-Force Measurement

In the field of consumer electronics that pursues extreme precision and reliability, Ligent Sensing continues to provide key technical support for various 3C product testing links with high-performance micro sensors such as LFS-02.We are committed to using stable, accurate and durable sensing solutions to help customers create smart electronic products with excellent user experience and rock-solid quality.