In the field of precision manufacturing, grinding and polishing processes play a vital role in the appearance and structural quality of products. However, the stability and consistency of such processes are often limited by the control of force changes during operation. Especially in the consumer electronics, automotive parts and precision mold industries, how to achieve stable and uniform grinding without damaging the workpiece has become a technical difficulty in the production process.The introduction of six-dimensional force sensors provides a higher-precision and higher stability for the robot grinding system.

Overview of Application Scenarios

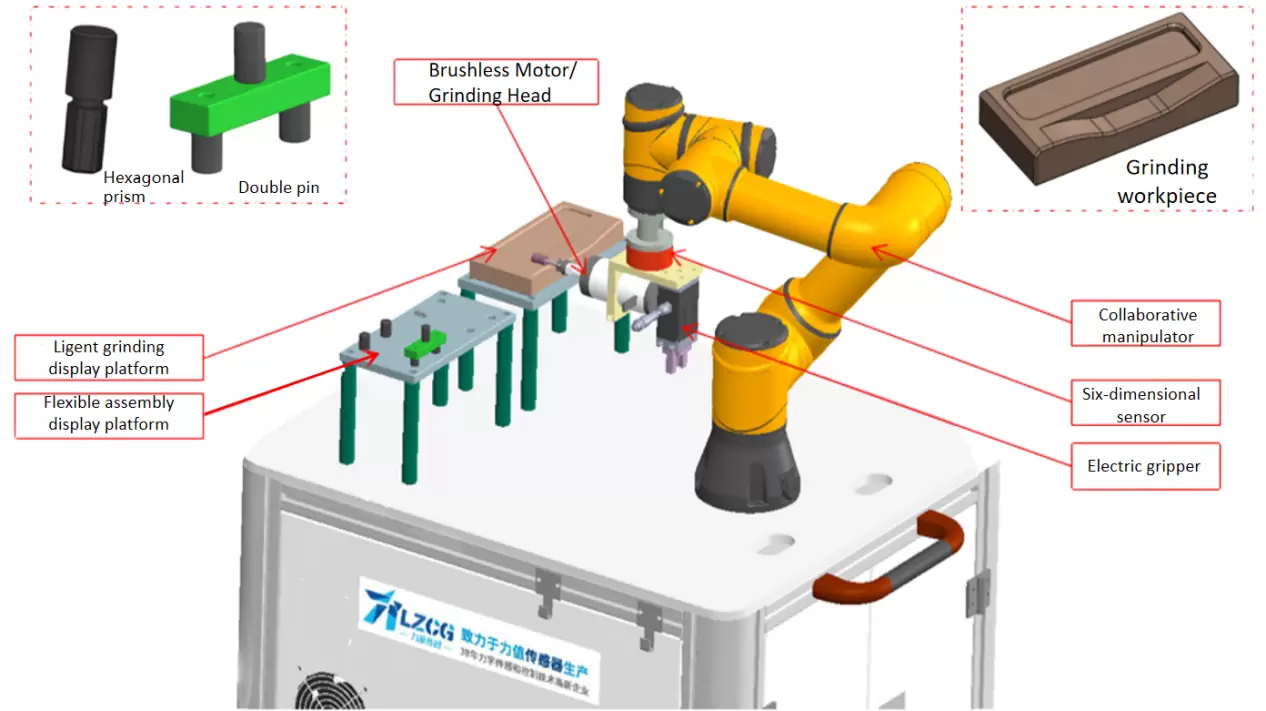

In this case, we integrate the LF-606F six-axis force sensor into a collaborative robotic arm system,and achieved precise grinding and polishing of complex curved surfaces by coordinating with the collaborative robot, electric gripper, brushless motor/grinding head and force-controlled grinding test platform.

During the dynamic grinding process, the sensor LF-606F can real-time collect the force of the XYZ three axes and the torque data around the XYZ three axes,so that the robot can dynamically and intelligently adjust the grinding path and applied force value, realize closed-loop control, and effectively addresses the grinding needs of workpieces with different materials, shapes, and hardness.

Application advantages of six-dimensional force sensors in grinding and polishing:

①Accurately control the grinding force

The sensor can real-time monitor and feedback the actual contact force value . When the force is too large or the direction is deviated, the system can immediately adjust the path and speed to effectively avoid uneven grinding, scratching or damaging the workpiece.

② Improve the quality of surface processing

The six-dimensional signal enables the robot to not only control "how much force to press", but also judge "whether there is torsion or offset", making the processing of 3D complex surfaces more sensitive and smooth.

③ Stable and Repeatable Grinding Process

Excellent repeatability and low hysteresis characteristics make each grinding action highly consistent, significantly improving product surface consistency and the yield rate.

④ Adaptability to Various fixtures

With a compact size and standardized signal output, the sensor is compatible with various end effectors (such as electric grippers and brush heads) and controllers, facilitating customer system integration and secondary development.

⑤ Real-time data collection and transmission

By using supporting instruments to collect data and analyze force curves, engineers can optimize grinding process parameters and improve the grinding effects.

Customer value Proposition:

By integrating the six-dimensional force sensor into grinding machines,customers not only realize the automation and standardization of the grinding and polishing process, but also significantly improve product consistency and yield rate, and reduce human errors and post-production repair costs.

If you have requirements for grinding force control, automated assembly, or other force-sensing applications,please contact us to learn more cases and technical solutions.