In industrial production, belt tension is a key factor affecting transmission efficiency, equipment life and production safety.An overly tight belt can lead to accelerated bearing wear and even breakage, while a loose belt is prone to slipping, affecting transmission accuracy and efficiency. Traditional tension testing mainly relies on manual experience or simple tools, facing challenges such as low accuracy, poor efficiency, strong subjectivity, and lack of data support, making it difficult to meet the needs of modern industry for stable operation.

To address the above pain points, Ligent Sensor has launched the LFZ - 25B series through - axis tension sensors to provide customers with more accurate, efficient and reliable solutions:

High-precision measurement: LFZ-25B series through-axis tension sensor adopts full-bridge detection method and an integrated design with special internal materials, which can effectively reduce measurement errors and greatly improve measurement accuracy and stability. Compared with the same type of sensors at home and abroad, it has higher accuracy and smaller errors.

Real-time and fast: With the cooperation of tension sensor, the detection equipment can realize real-time monitoring of belt tension and significantly improve test efficiency.

Data analysis: By cooperating with the matching instrument of Ligent, the measured tension data can be real-time transmitted to the host computer, and engineers can carry out secondary analysis and optimization of the data.

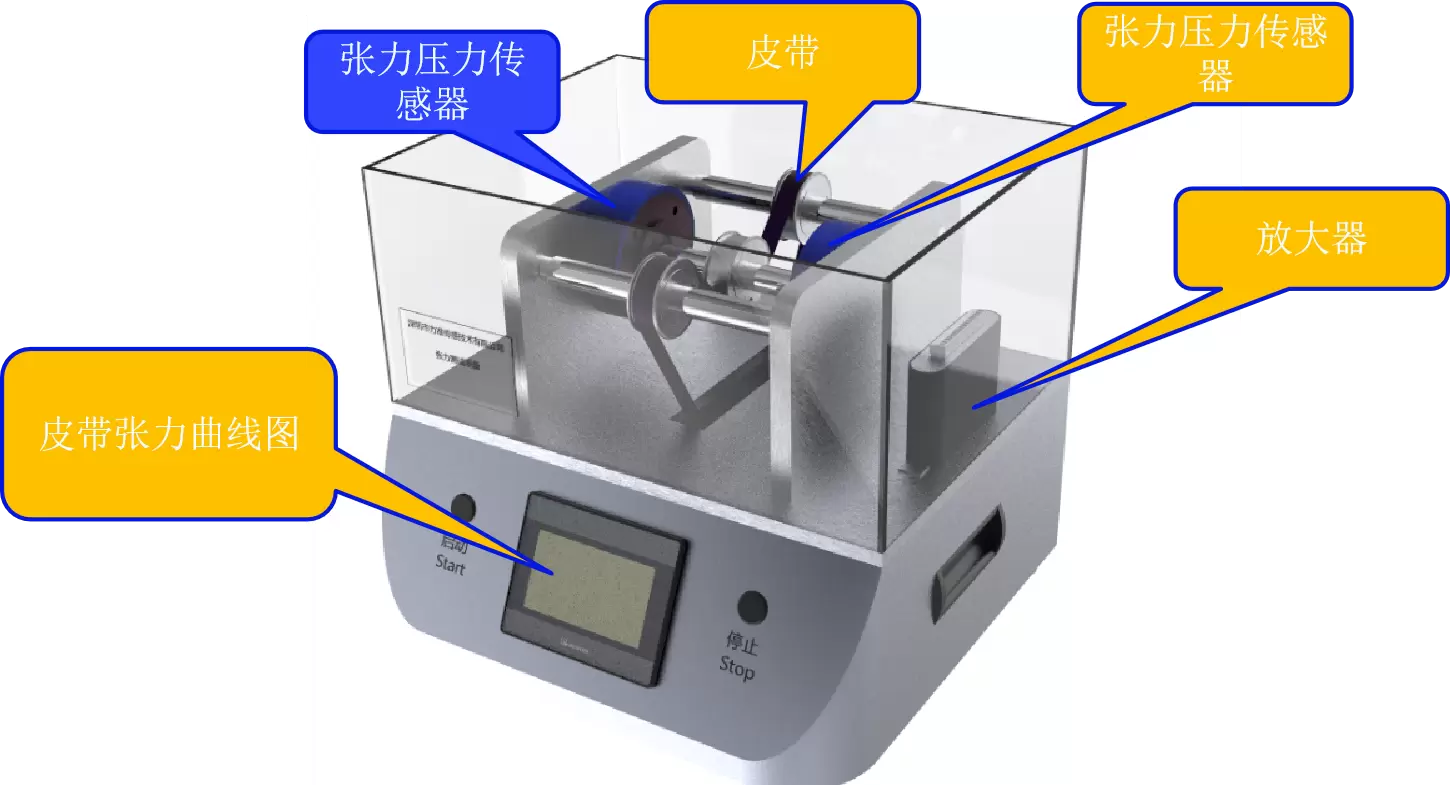

Convenient installation: Through-shaft design:The central hole allows direct shaft penetration for simple installation. The sensor provides a variety of installation options such as flange and shaft-table mounted.The sensor is small and compact,it is easy to integrate into various belt tension test equipment,without the need for users to make complex modifications to the detection equipment.

Applicable scenarios of LFZ-25B tension sensor:

Belt manufacturers:Verify whether belt tension meets standards to ensure product quality.

Machinery Equipment Manufacturers: Evaluate the performance of belt drive systems to optimize equipment design.

Industrial Production Lines: Monitor belt tension in real-time to prevent equipment failures and improve production efficiency.

Automobile manufacturing:Detect the tension of engine belts and transmission belts to ensure safe operation of vehicles.

Textile industry:Control belt tension in textile machinery and improve textile quality.

With its excellent performance, the LFZ-25B tension sensor from Ligent has become an ideal choice for solving traditional tension testing challenges and ensuring stable operation of equipment Ligent has been continuously innovating for 40 years and is committed to providing customers with better intelligent solutions.