Servo press systems are commonly applied in automated industrial production,such as engine and transmission system installation, battery, chassis and body parts press assembly in the field of new energy vehicles.In addition, medical products, electronics and household appliances industries, and power tool manufacturing industries are also important application areas for servo press systems.

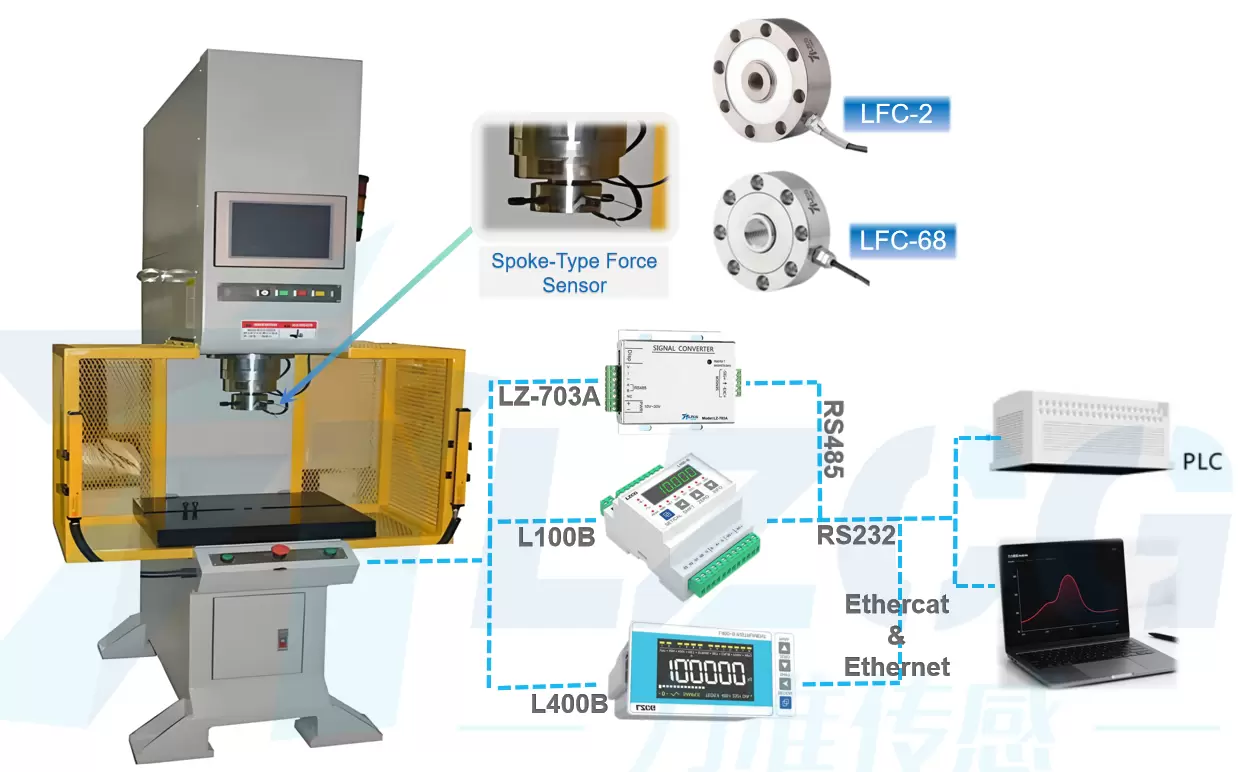

A servo press usually consists of a press module (also called a "press spindle"), a servo amplifier and a force displacement evaluation unit. It is also equipped with a process monitoring system to monitor the force value during the press process. The system evaluates and records the force value changes during the press and assembly process based on the data provided by the pressure sensor.

Why choose a spoke-type pressure sensor?

(1)The sensor structure is designed to adapt to the working conditions of the servo press

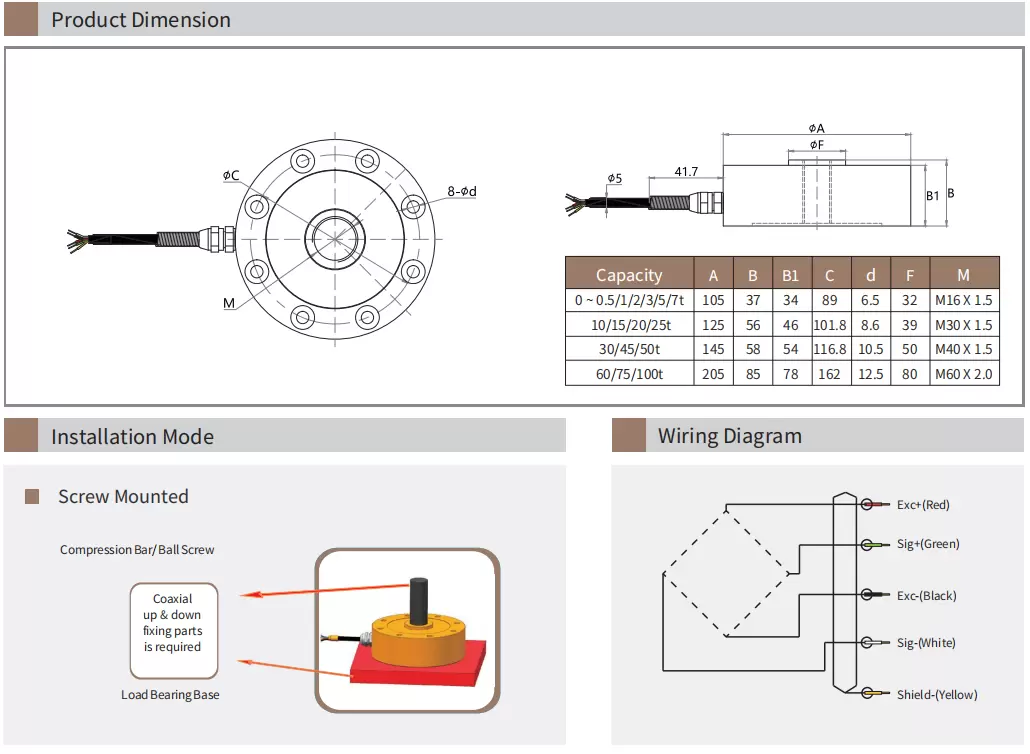

Strong anti-eccentric load capability of spoke-type structure: Different from column-type or S-type sensors,spoke-type sensors (such as LFC-2 and LFC-68) are designed to offset lateral force interference when the force application point is centered. In eccentric loading scenarios (e.g., asymmetric press-fitting),the error is ≤0.5%,while the error of traditional sensors may be more than 2%.

Low profile and strong overload resistance:The sensor is small in height and adapts to the compact body structure of the servo press. At the same time, it has strong overload resistance, avoiding the deterioration of sensor performance due to overload deformation of the sensor.

(2)High measurement accuracy

Industrial-grade measurement accuracy: Taking LFC-2 as an example, the full-scale measurement error is ±0.05%F.S., and the repeatability accuracy is ±0.05%,enabling it to capture subtle force value changes.It can capture subtle changes in force values. The selection of multiple ranges is suitable for the press-fitting of different products (such as electronic chip bonding pressure control).

(3) Industrial-grade stability

Full-protocol communication adaptation: supports RS485, RS232, EtherCAT, Ethernet and other interfaces,and can be seamlessly connected to PLC and force analysis software (such as 5300 series) to achieve real-time data upload and process traceability.

Anti-interference design: The sensor adopts a fully sealed welding process(protection class IP68) and built-in temperature compensation circuit (can be used normally in -20℃~80℃ environment),maintaining stable output in the strong electromagnetic interference and oily environment of the stamping workshop.

(4) Force value closed-loop control and data traceability:

Set the pressure-assembly force threshold and the sensor provides real-time force feedback.When the force exceeds the upper limit, the servo motor automatically decelerates, and the error is controlled within ±0.5%.The force-displacement curve of each press can be recorded by the force analysis software, and the abnormal batch can be traced back through the specific sensor data, which significantly improves the quality inspection efficiency.