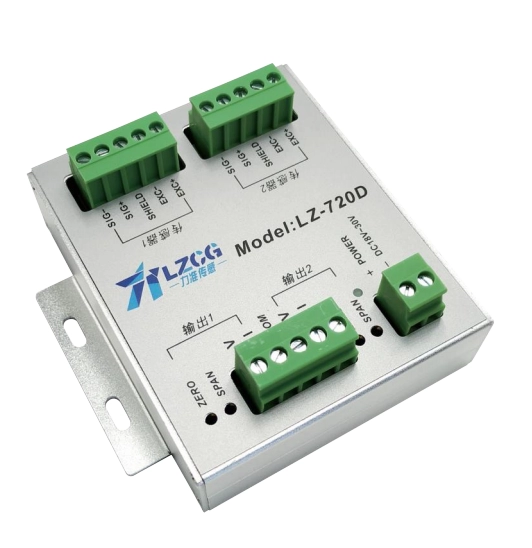

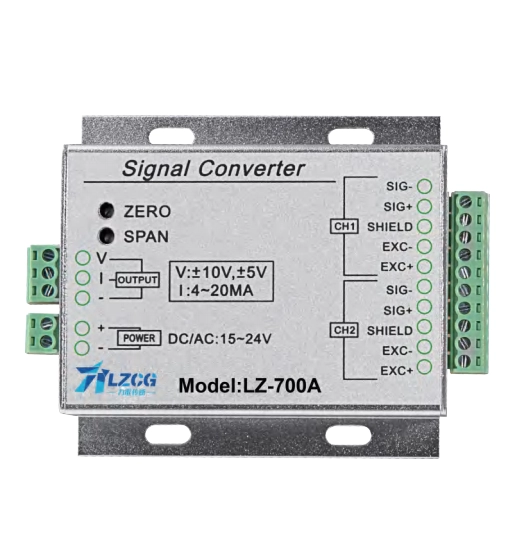

LZ-720D is assembled with aluminum housing and high performance original components.

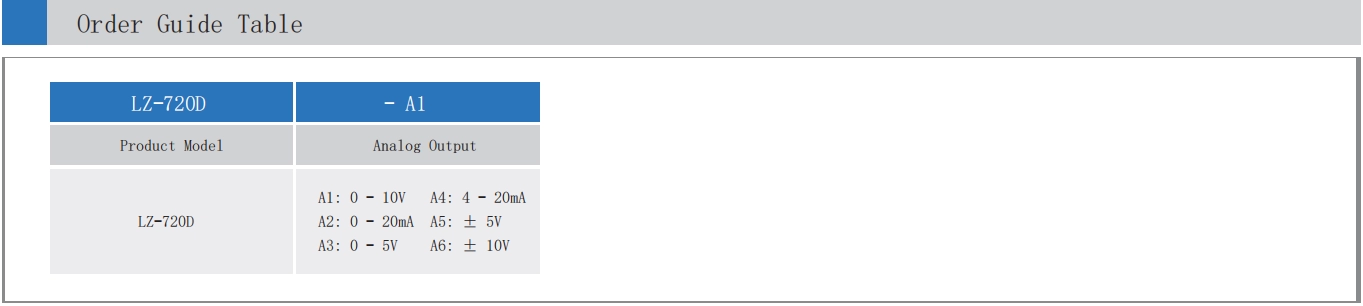

It performs voltage stabilization, constant current bridge supply, voltage and current conversion, impedance adaptation, linear compensation, and temperature compensation. Convert the mechanical quantity into standard current and voltage signal output, which can be switched between 0-10mA, 0-20mA, 4-20mA, 0~± 5v, 0~± 10v. It can be directly interfaced with automatic control equipment such as PLC, single chip microcomputer, upper computer terminal, or networked to a computer. It has standard signal external zero adjustment and external gain

adjustment functions, input overvoltage protection, and output short circuit protection.

EN

EN