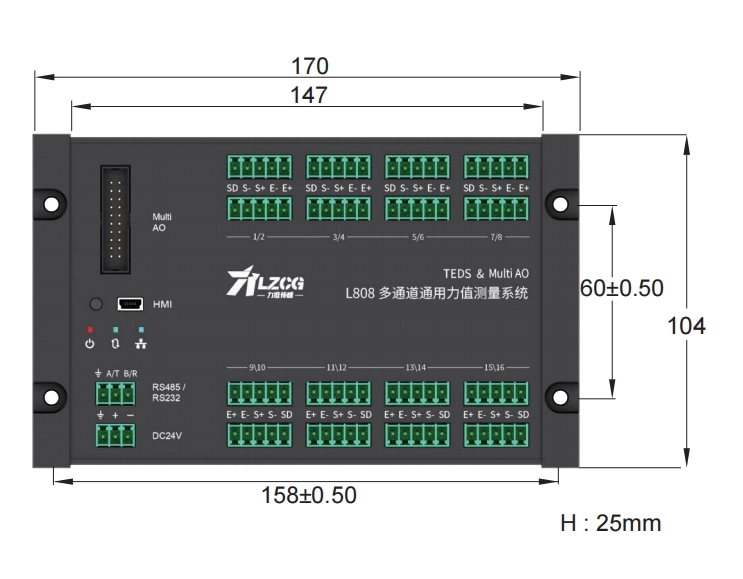

The L808 digital transmitter features two communication interfaces: C2 (RS232) and C4 (RS485). It supports up to 16 channels, with selectable analog outputs including A1 (0–10 V), A2 (0–20 mA), A3 (0–5 V), A4 (4–20 mA), A5 (±5 V) and A6 (±10 V). The device is also equipped with the TEDS function.

EN

EN