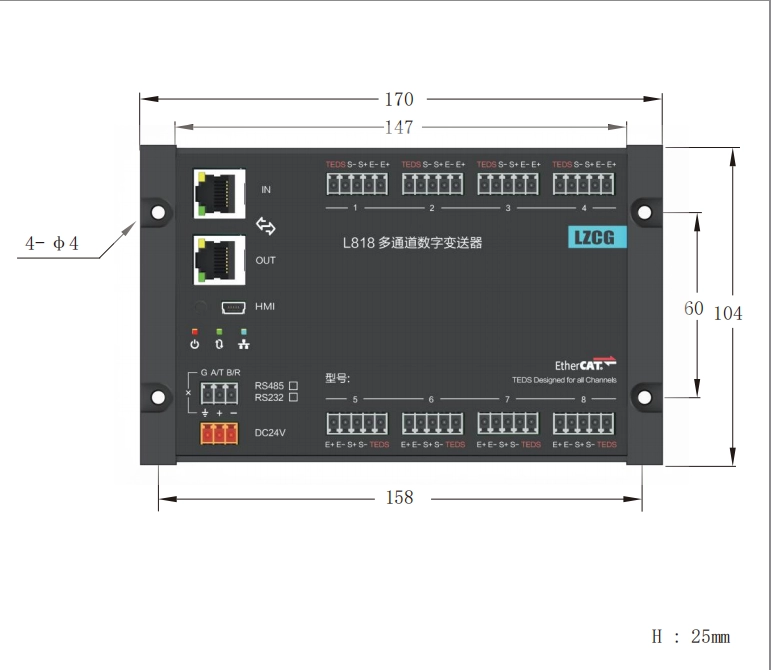

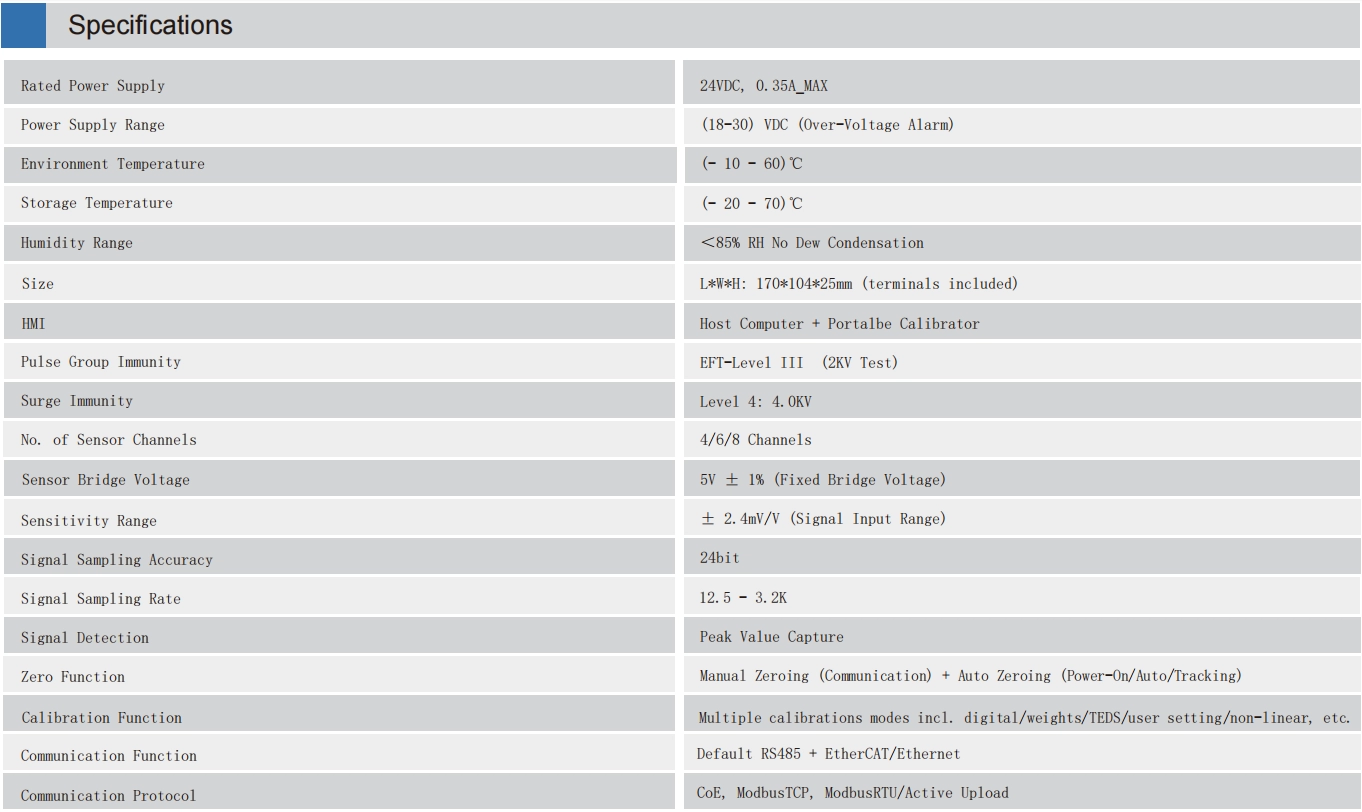

The L818 is a digital transmitter. The L808E digital transmitter is equipped with dual communication interfaces (EtherCAT and Ethernet), and supports up to 8 acquisition channels. Boasting 24-bit precision and a sampling rate range of 12.5 to 3.2K, this device also integrates the TEDS (Transducer Electronic Data Sheet) function for enhanced usability. For installation flexibility, it is compatible with 35mm guide rail mounting as well as screw fastening (supporting both horizontal and vertical orientations) function.

EN

EN