Sep 24Source: LZCGIntelligent Browse: 164

Load cells play a crucial role in various industrial systems, providing precise measurements of force, weight, and tension. However, when exposed to harsh conditions—such as extreme temperatures, moisture, dust, or chemicals—these sensors can fail prematurely. As a trusted load cell manufacturer, Shenzhen Ligent Sensor Tech Co., Ltd. offers practical advice and innovative solutions to ensure the longevity and optimal performance of your load cells in demanding environments, particularly in applications like the automation industry, consumer electronics, and other sectors.

Common Causes of Load Cell Failure

Understanding the causes of load cell failure is the first step toward preventing it. In challenging environments, load cells face several risks that can impact their performance, including:

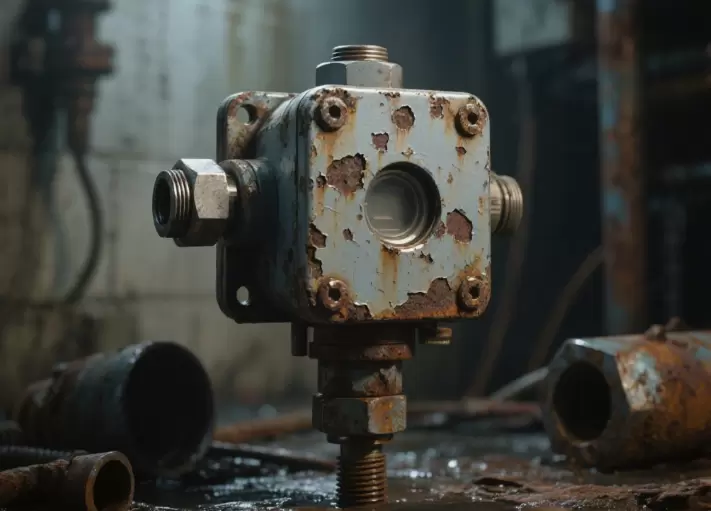

Corrosion and moisture ingress: Exposure to moisture and chemicals can degrade the sensor over time.

Mechanical overload or shock: Excessive force can cause permanent damage to the load cell’s internal components.

Electrical interference: Poor grounding or electrical noise can disrupt signal integrity.

Temperature fluctuations: Extreme heat or cold can affect sensor accuracy and durability.

Improper installation or handling: Incorrect mounting or over-tightening can lead to sensor damage.

By identifying these risks early, you can take steps to extend the lifespan of your load cells and ensure they continue to provide accurate measurements.

Protection Measures for Force Sensor

Environmental Sealing and Housing

●Choose load cells with a high IP67 or better ingress protection rating, ensuring they are resistant to dust, moisture, and contaminants.

●Use hermetically sealed units for environments where high humidity or exposure to corrosive chemicals is a concern.

●Consider protective enclosures or covers to shield sensors from physical impacts and chemical exposure.

Corrosion Resistance

●Select force sensors made from stainless steel or those with corrosion-resistant materials.

●Regularly inspect for rust, wear, or chemical damage and apply anti-corrosion coatings when necessary.

Temperature and Thermal Protection

●For areas with extreme temperature fluctuations, install thermal insulation or shielding around the load cells.

●Use temperature-compensated load cells to maintain accuracy, even in extreme environments.

●Ensure that sensors are not exposed directly to heat sources or subject to rapid temperature changes.

Wiring and Grounding Best Practices

●Use shielded cables to minimize electrical noise and ensure proper grounding to reduce signal interference.

●Inspect connectors regularly for wear, corrosion, or loose connections.

Routine Inspection and Calibration

●Schedule regular inspections for physical damage, wear, or performance issues.

●Periodically calibrate load cells to maintain measurement accuracy and document maintenance activities for performance tracking.

Real-World Applications

In industries such as consumer electronics and industrial automation, force sensors are essential for ensuring quality and precision. For example, in robotics, the sensors are critical for measuring forces applied by robotic arms, while in consumer electronics, force sensors ensure the proper handling and testing of sensitive components. Whether you're dealing with heavy machinery or intricate microelectronics, the right protective measures will extend the service life of your force sensors and maintain operational efficiency.

Frequently Asked Questions

1.How often should load cells be calibrated in harsh environments?

In environments with extreme conditions, it’s recommended to calibrate your load cells every 6 to 12 months, or more frequently depending on usage and exposure to harsh elements.

2.Can protective coatings extend the lifespan of load cells?

Yes, applying protective coatings significantly reduces the risks of corrosion, abrasion, and moisture damage, which in turn extends the life of your load cells.

3.What are signs that a load cell may fail?

Signs of impending failure include drifting readings, erratic outputs, or zero shifts. Physical indicators, such as cracked housings or frayed cables, may also signal potential issues.

Final Thoughts: Invest in Load Cell Protection for Long-Term Performance

Operating in tough environments doesn’t have to mean sacrificing sensor reliability. By investing in high-quality force measuring instruments from Ligent Sensor, incorporating protective measures, and scheduling regular maintenance, you can ensure the longevity and accuracy of your load cells. Our products, trusted across industries like consumer electronics, industrial automation, and more, provide exceptional performance, reliability, and resilience, helping you avoid unexpected breakdowns and keep your operations running smoothly.

TDK (Title, Description, Keywords)

Title: How to Protect Load Cells for a Longer Service Life | Ligent Sensor

Description: Learn how to extend the lifespan of load cells with protection strategies for harsh environments. Choose Ligent Sensor for reliable force measuring instruments and load cell solutions designed for automation industries and consumer electronics.

Keywords: Load cell manufacturers, load cell types, force measuring instrument, consumer electronics, automation industry, load cell protection