Digital control indicator convert millivolt signals into clean, reliable outputs ready for DAQ, PLC, and control system integration.

They are trusted by engineers worldwide to deliver best-in-class performance in a wide range of applications including Hydraulic/pneumatic systems, medical, automation and robotics,with the versatility, accuracy, and service support that make a trusted partner for mission-critical systems.

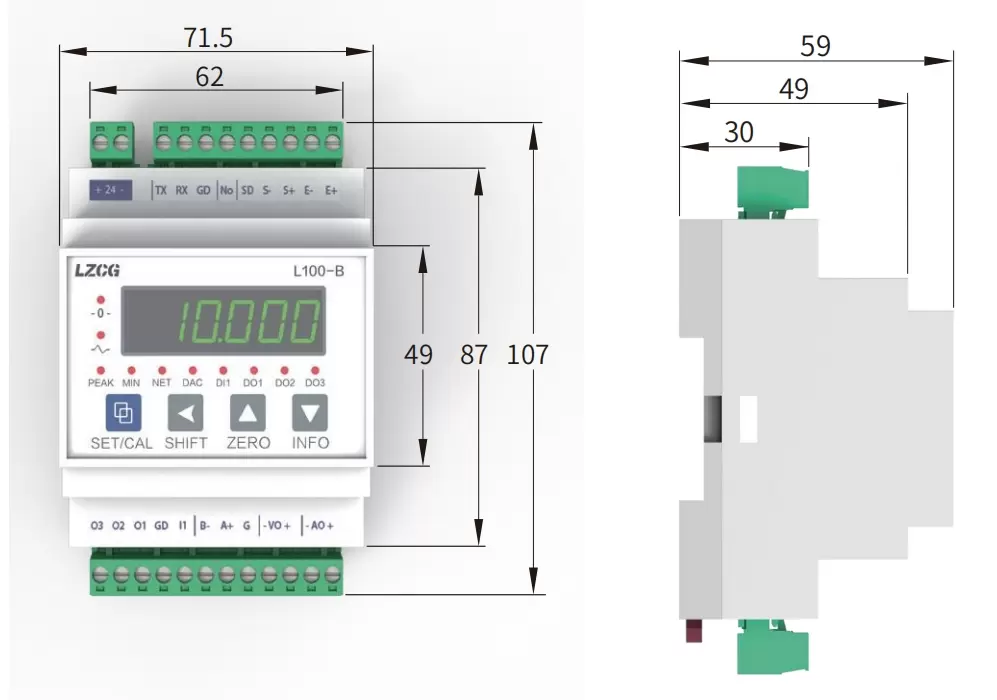

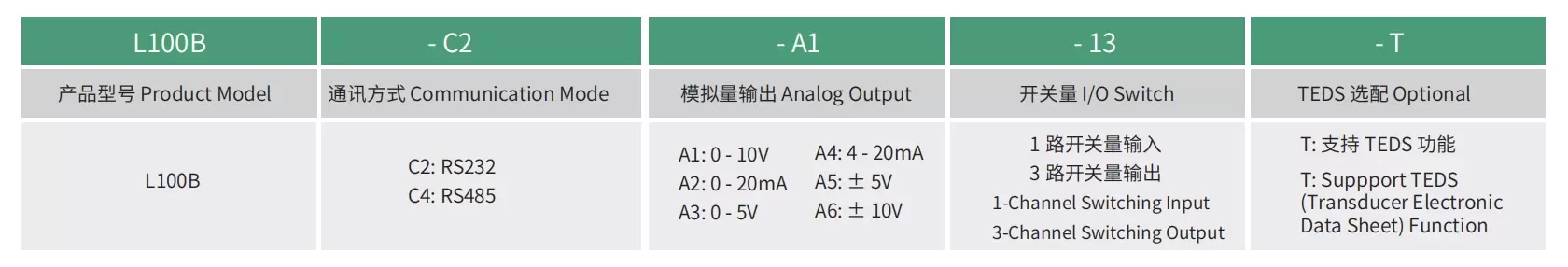

L100B's communication mode includes RS232 and RS485;The analog output includes A1(0-10V), A2(0-20V),A3(0-5V),A4(4-20mA), A5(±5V),A6(±10V)Besides,it has 1-channel switching input and 3-channel switching output can be choosed.And the indicator suopports TEDS(Transducer electronic date sheet ) function

EN

EN