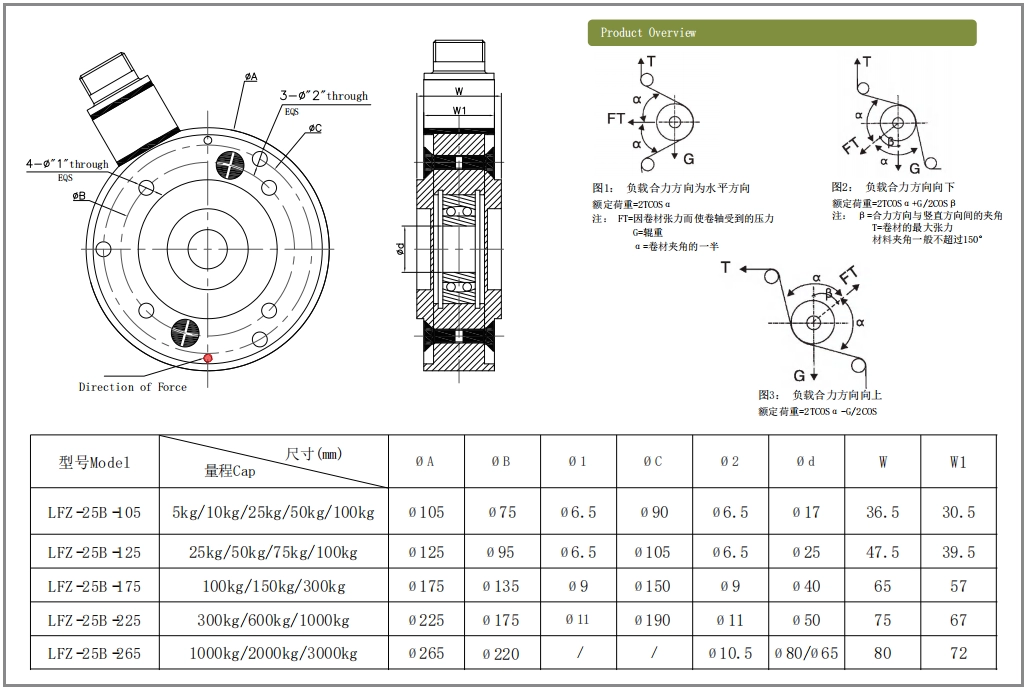

1. Structural features: High-precision tension measurement for cables, wires, films & belts;Stable performance with low signal drift, reliable real-time monitoring ; Compact modular design, space-saving & easy for maintenance

2. Core advantages: Wide tension range adaptation, compatible with diverse linear materials;High measurement accuracy, ensuring stable production quality;Durable construction, long service life in industrial working conditions

3.Installation advantages: Simple mounting, direct alignment with tensioned materials;Compact size, fits limited installation spaces in production lines

EN

EN