1. Structural features:

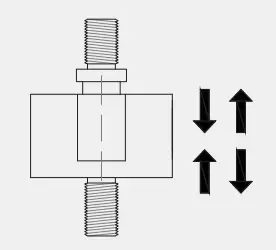

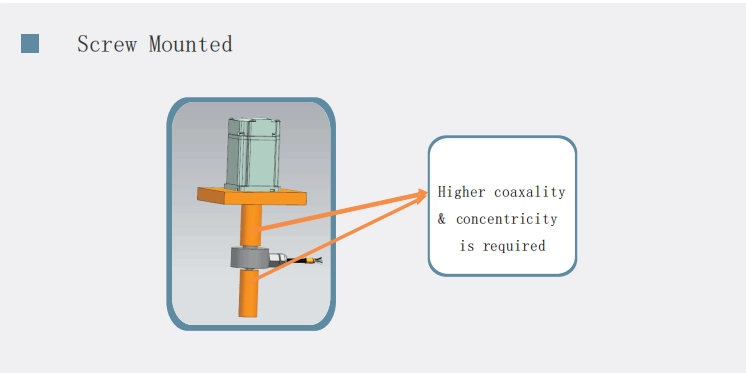

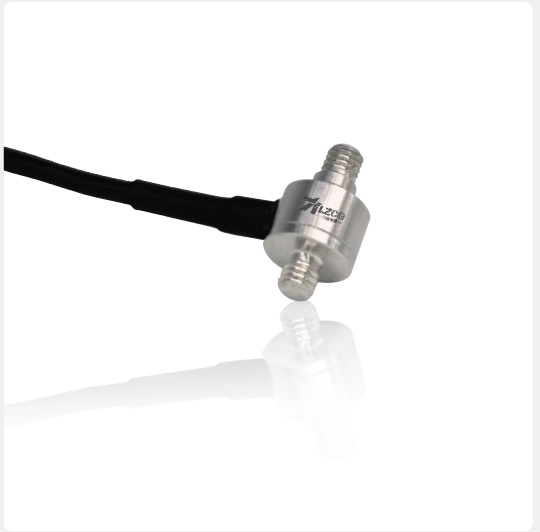

Pull Rod Structure: Adopts a pull rod design with a simple structure, ensuring the installation process is convenient and efficient .

Installation convenience: No complex tools or additional accessories are required, and it can be quickly integrated into various types of equipment.

2. Core features

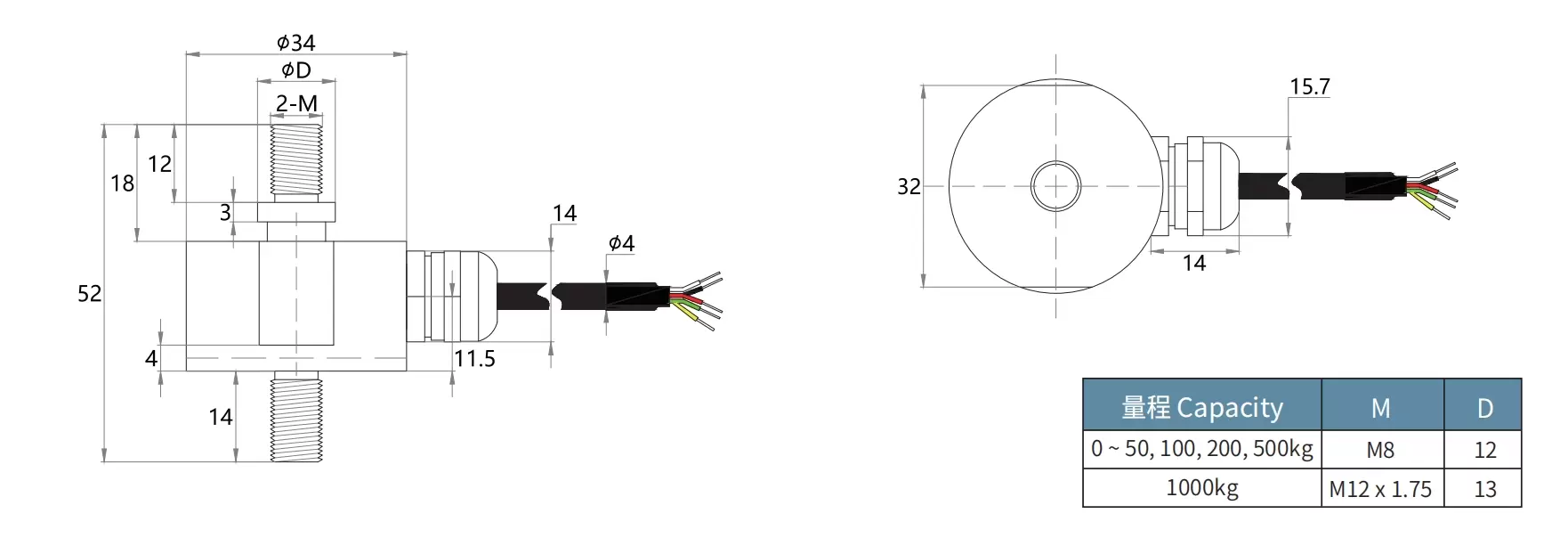

Compact and small: The overall volume is compact and takes up very little space, especially suitable for scenes with limited installation space.

High-precision detection: With high sensitivity and accuracy, it can accurately capture force value changes in real time to meet the needs of force detection and control.

Spatial Adaptability: Particularly suitable for devices with limited installation space (such as small machinery, precision instruments, etc.), without affecting the overall layout of the equipment.

3. Dynamic performance

Response frequency: The dynamic response frequency is ≤200Hz, effectively addressing the dynamic force monitoring requirements of scenarios such as industrial automation production lines, medical devices, and automated testing equipment, ensuring the timeliness and reliability of data collection.

EN

EN