Weighing load cell’ structural features

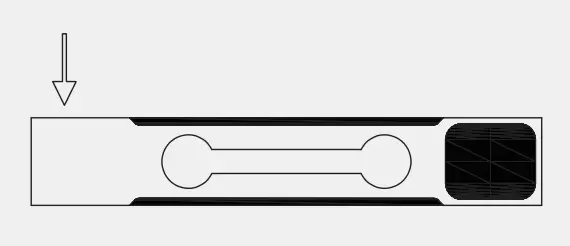

1.Core structure: It adopts parallel beam structure,where the elastic body of the sensor consists of two or more parallel beam-like structures. When subjected to force, the beam body undergoes slight deformation.Strain gauges attached to the beams convert this deformation into electrical signals to realize weight measurement.

2.Structural Advantages: The design of parallel beams ensures a clear and uniform force transmission path,which can effectively convert vertical weight loads into bending deformation of the beams,making it easy for the strain gauge to accurately capture the signal, laying the foundation for high-precision measurement.

EN

EN