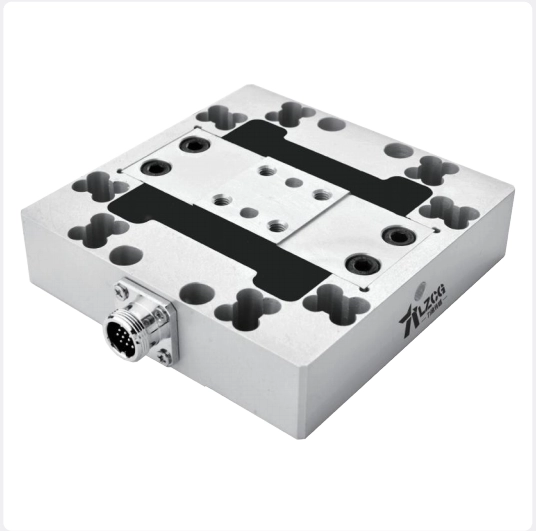

A multi-dimensional force sensor is a precision device that can accurately measure forces in multiple directions in space (such as forces on the X, Y, and Z axes and moments around the axes) at the same time. It achieves synchronous detection of multi-dimensional force signals through elastic body deformation transformation, strain gauge signal conversion, and decoupling algorithm processing.

Features:

Multi-dimensional synchronous measurement;

Anti-interference and low coupling;

Wide adaptability;

EN

EN